Content

- Why Precast? (Benefits) - thin brick formliners

- Recommendation Images - thin brick form liners

- Complete Introduction Of Attractive Concrete Form Liners - thin brick concrete formliners

- Take Into Consideration Clean-and-seal As An Alternative Finish For Indoor Concrete Floorings - concrete formliners thin brick

- Job Honors - thin brick form liners

Why Precast? (Benefits) - thin brick formliners

Benefits of Use Formliners

A lot of formliner suppliers have the capability to generate custom-made materials, expanding the worlds even better for developing style. Formliners are initially created from a master mould, which can be established from components located in nature, crafted by an artisan, or through use of computer system mathematical control (CNC) milling machinery.On completion of the master mould for the customized formliner, the style specialist will either approve the style or suggest adjustments. As soon as accepted, the master mould will ultimately be utilized to cast formliners a precast maker or service provider will certainly employ to generate the architectural concrete element. Depending on the arrangement in between the formliner maker and the task developer or proprietor, the customized mould may be retired or become the property of the project proprietor. This might additionally improve originality, especially if the custom formliner is reserved for that particular task.

New modern technology permits the style expert to think even further outside package. Photoengraved and also 3-D alleviation formliners offer life-like images never prior to feasible in concrete or masonry design. There has constantly been a pursuit to include esthetically pleasing aspects into building façades. One of the most respected examples are found in early Greek and also Roman style. Abundance in these two societies was deeply rooted and revealed with luxurious building exteriors. These layouts were so excellent numerous elements of modern design can be traced to those eras. The luxuriant columns and also hand-cut stone building blocks make a vibrant declaration with esthetics, but likewise provided feature. So much 'function' actually, the grandest of these frameworks are more than 2 centuries old. The very early developers and fabricators of these ancient structures were setting the stage for a 'drab-to-fab' revolution in structure exterior architectural coatings.

- Plastic type liners are typically used a vacuforming process.

- The two a little conic halves of the mould can be held together with the help of boards as well as clamps for casting the baluster.

- In April, the company additionally prepares to offer kinds that are 8-, 10- and also 12-inches broad.

- A formliner can be a cost-effective means to provide concrete a distinctive, imaginative appearance.

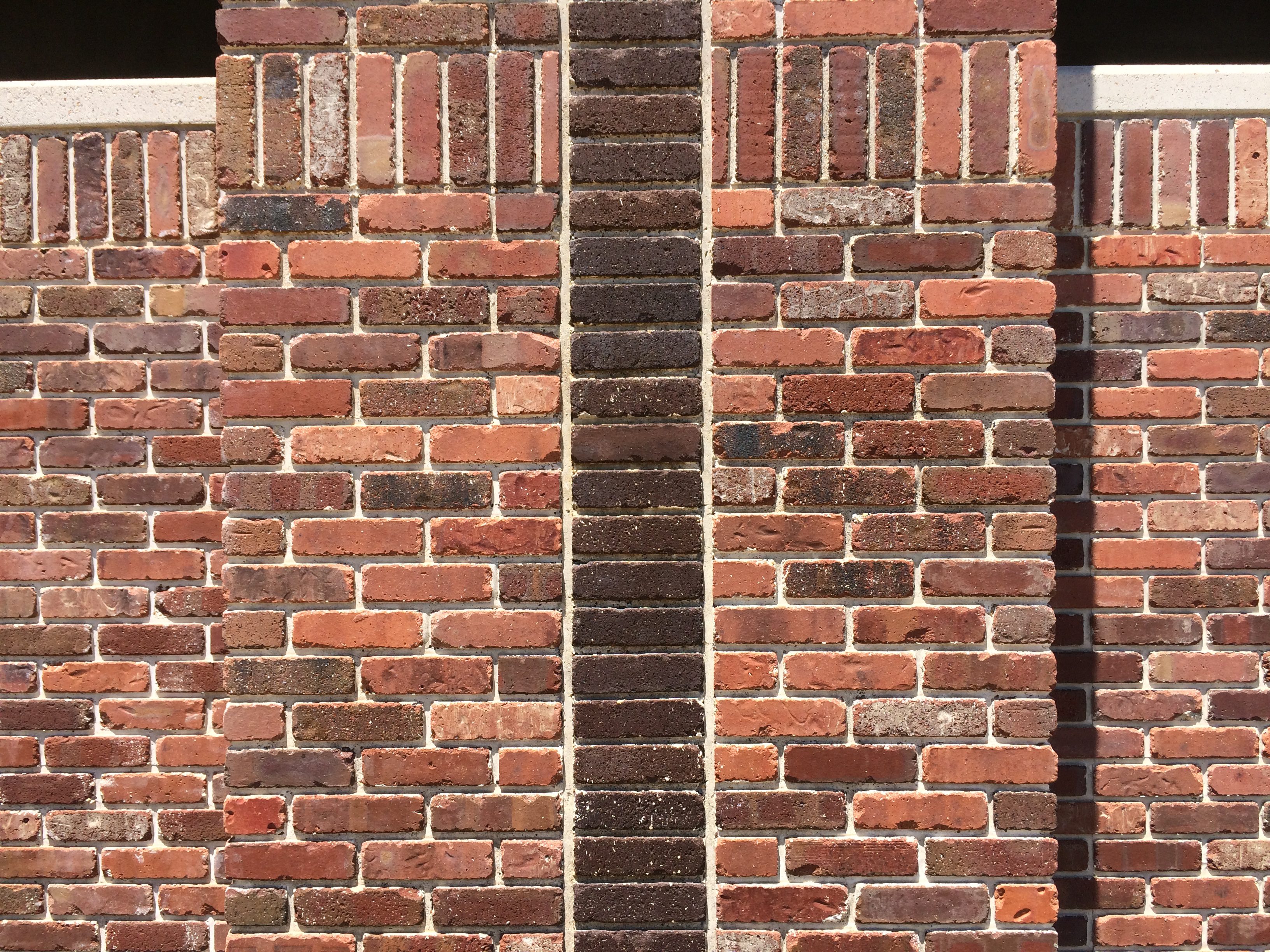

- Reproducing block and block, 2 of the most timeless structure materials is very easy.

- Pacific Formliner is offered in a flexible, re-usable PFL and also inflexible EPS.

Early constructing style and products were relegated to what was conveniently available from the planet. Egyptians utilized straw, mud, gypsum, as well as lime to form traditionals in the construction of the pyramids. The Romans made use of a material comparable to modern concrete and incorporated it with animal items that acted as admixtures. Nevertheless, it was not until 1824 when England's Joseph Aspdin generated portland concrete. As the cornerstone in concrete, this material catapulted the layout and building and construction industry ahead. The century following Aspdin's creation saw many historical firsts within concrete construction, from the very first enhanced bridge in 1889 (San Francisco) to the first high-rise in 1903 (the Ingalls Building in Cincinnati). Concrete and also concrete masonry systems (CMUs) quickly ended up being the building and construction material of selection for many developers throughout the globe.

Extended-use, Elastomeric Type Linings From Fitzgerald Formliners - thin brick form liners

With this improvement, came the increased wish for patterns, appearances, website and colours. Coloured concrete was presented in 1915 when Lynn Mason begain creating colour ingredients for concrete; a half-century later, produced patterns became possible. With the development of formliners, formed concrete once only possible through handcrafting might currently be replicated in a controlled and also more suitable fashion while preserving the timeless look borrowed from old style. In the 1970s, formliner manufacturers were able to include textures. Kinds of formliners: Contemporary formliners provide an almost unlimited variety of pattern and also texture chances. North American suppliers provide a conventional option of products, with some providing greater than 300 selections.

In the 1970s and 80s, ribbed patterns were commonly made use of in layouts for sound walls, commercial structures, mass transit stations, as well as various other numerous building exteriors. As polyurethane formliners emerged, the ribbed patterns gave way to even more all-natural and special patterns. This supplied the engineer with even more alternatives and flexibility when developing a concrete building outside. Patterns and also appearances formerly only available by extracting them from all-natural products are currently exactly replicated in formliners. Even the most standard structure materials, brick and block, have been recreated. Rock, timber, stucco, stonework, and also abstract esthetics can all be included in designs.